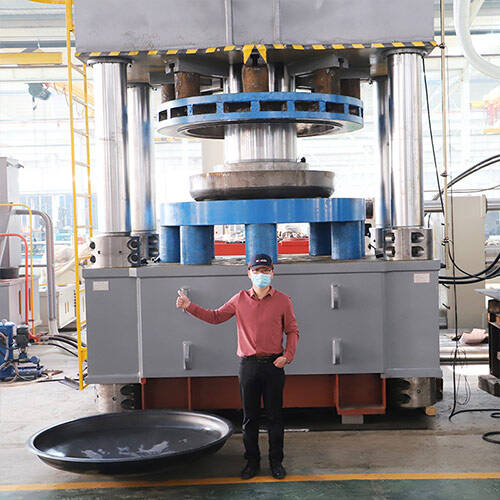

Ასეთი ჰიდრავლიკური პრესები მნიშვნელოვანია მაღალი სიზუსტის მქონე სამუშაო მეთოდებისთვის. ეს სიმძლავრის მქონე მოწყობილობა იყენებს სითხის წნევას ძალის შესაქმნელად, რაც ზუსტად უზრუნველყოფს მასალების გაჭრას და ფორმირებას ყოველ ჯერზე. წარმოების სფეროში, სიზუსტე მნიშვნელოვანია, მიუხედავად იმისა, რომ იწარმოება ლუქსური საათები თუ მასობრივი ბაზრის სქემები, ხოლო ჰიდრავლიკურ პრესებს მნიშვნელოვანი როლი აქვთ იმის უზრუნველსაყოფად, რომ თქვენი პროდუქტები იყოს უმაღლესი სტანდარტის. მაშ, რა სარგებლობა მოაქვთ ჰიდრავლიკურ პრესებს მაღალი სიზუსტის დამუშავების პროცესში და როგორ ეხმარებიან ისინი ხარისხის მუდმივობის უზრუნველყოფაში მასობრივ წარმოებაში?

Ჰიდრავლიკური პრესების სარგებლობა მაღალი სიზუსტის მქონე წარმოებისთვის

Მთავარი მიზეზი, რის გამოც ჰიდრაულიკური წნევები ეს არის პოპულარული არჩევანი მაღალი სიზუსტის წარმოებისთვის. ეს არის გზა, რომლითაც შეუძლიათ უზარმაზარი ძალის გამოყენება წარმოუდგენელი სიზუსტით. ეს სიზუსტე ხელს უწყობს რთული კომპონენტების, პატარა ინსტრუმენტების და ნაწილების წარმოებას, რომლებიც ზუსტად გემოვნებიან. ყველაფერი ზუსტად ისე იქნება, როგორც თქვენ გჭირდებათ. ჰიდრავლიკური პრესები შეუძლიათ გამოიყენონ სრული ძალა წვეთის ნებისმიერ წერტილში, ასე რომ სამუშაო ნაწილები თითქმის ყოველთვის განიცდიან ერთიან წნევას მთელ ზედაპირზე, ყურადღების გამახვილების ან გადახრის გარეშე. ასეთ სექტორებში, როგორიცაა საჰაერო-კოსმოსური, საავტომობილო და სამედიცინო მოწყობილობები, სადაც უმცირესი გადახრა შეიძლება სერიოზული შედეგები გამოიწვიოს, მწარმოებლებისთვის ეს დონის სიზუსტე კრიტიკულია.

Ბოლო, მაგრამ არა უმნიშვნელოვანესი, ჰიდრავლიკური punches შეუძლია მუშაობა ფართო სპექტრი მასალები. იქნება ეს ლითონი, პლასტმასი, რეზინი ან სხვა კომპოზიტული მასალები, ჰიდრავლიკური პრესები ადვილად შეიძლება ფორმირება და ფორმირება სხვადასხვა მასალა მოთხოვნები ინდივიდუალური ინდუსტრიები. ეს მოქნილობა ხდის ჰიდრავლიკურ პრესს კარგი არჩევანი მწარმოებლისთვის, რომელსაც სურს წარმოება სხვადასხვა სხვადასხვა ნაწილები და კომპონენტები, ასევე მაღალი დონის სიზუსტით. ჰიდრავლიკური პრესები ასეთი აზროვნება მნიშვნელოვანია მაღალი სიზუსტის წარმოებაში, როდესაც შეფერხება შეიძლება გამოიწვიოს დაგვიანებით და შეფერხებით წარმოების ხაზის გასწვრივ.

Ჰიდრავლიკური პრესები საკმაოდ მარტივია და მარტივია მომსახურება. მათი ტრენინგის და უნარების შენარჩუნების საშუალებით ამ პრესის გამოყენებისათვის, ოპერატორებმა ხელი შეუწყვეს ჰიდრავლიკური პრესების ეფექტურობის შენარჩუნებას და სიცოცხლის ხანგრძლივობას ისე, რომ ხარისხი და შესრულება შეინარჩუნეს მთელ მასობრივ წარმოებაში. ჰიდრავლიკური პრესის მანქანა მუშაობს როგორც მექანიკური პრესები, გარდა რამდენიმე უმნიშვნელო განსხვავებისა. და ერთ-ერთი საუკეთესო გამძლეობა, რომლის შესახებაც უნდა ვისაუბროთ, ის არის, რომ ის შეიძლება ბევრად უფრო მოკლე დროში დაყენდეს, ეს საშუალებას მოგცემთ შეცვალოთ თქვენი სამსახური, მიზეზი კი ისაა, რომ მოკლე დაყენების დრო. ჰიდრავლიკური პრესების უპირატესობები მაღალზუსტ წარმოებაში აშკარაა - ისინი გთავაზობთ სიზუსტეს, მრავალფეროვნებას და გამძლეობას გონივრულ ფასად.

Როგორ ქმნიან ჰიდრავლიკური პრესები ერთგვაროვან ხარისხს მასობრივ წარმოებაში

Ერთგვაროვნება მნიშვნელოვან ფაქტორს წარმოადგენს მასობრივ წარმოებაში, და უნდა უზრუნველყოფდეს მეთვალყურეობას იმაზე, რომ ათასობით პროდუქი მკაცრ სტანდარტებს აკმაყოფილებს. ჰიდრავლიკური პრესები ერთ-ერთი ძირეული მოწყობილობაა, რომელიც საშუალებას იძლევა ასეთი დონის მუდმივობის მიღწევას, რადგან უზრუნველყოფს მასალის ფორმირებას ან დამუშავებას კონტროლირებად და სტაბილურ გარემოში. სიზუსტე ფრეიმის ჰიდრაულიკური წვევი ნიშნავს იმას, რომ რამდენიმე კომპონენტი და ნაწილი შეიძლება წარმოიებოდეს მცირე განსხვავებით, რათა მთელი წარმოების პროცესი იყოს მუდმივი და საიმედო. ეს საიმედოობა აუცილებელია მომხმარებლის მოლოდინების და ინდუსტრიის სტანდარტების დასაკმაყოფილებლად იმ სფეროებში, სადაც პროდუქის ხარისხი პირველ რიგში მნიშვნელოვანია.

Ამასთან, ჰიდრავლიკური პრესები საშუალებას აძლევს მომხმარებლებს დააკონტროლონ და მოარგონ წარმოება ონლაინში, რათა დაცვან ხარისხის სტანდარტი. წნევის, სიჩქარის და სითბოს პარამეტრების კონტროლი უწყობს ხელს ნაწილების წარმოებაში სასურველი ზომებით და მახვილებით არანაირი შეცვლის გარეშე. სისტემის ასეთი დონის კონტროლი და მონიტორინგი განსაკუთრებით მნიშვნელოვანია მაღალი და ზუსტი წარმოების შემთხვევაში, რადგან უმნიშვნელო გადახრებიც კი შეიძლება გავლენა მოახდინოს ბოლო პროდუქის შესრულებაზე და უსაფრთხოებაზე. ამ ხარისხის სტანდარტების შენარჩუნება შესაძლებელია მასობრივი წარმოების მეშვეობით ჰიდრავლიკური პრესების საშუალებით, რომლებიც ერთდროულად არიან საიმედო და ზუსტი. გარდა ამისა, ჰიდრავლიკური პრესები არიან.

Ჰიდრავლიკური პრესები ერთგვაროვნობის მიღწევის გარდა ხელს უწყობს ნაგავის და ხარჯების შემცირებას გარდაქმნის პროცესში, რის შედეგადაც მწარმოებლები შეძლებენ ნაგავის, ნაკლები ხარისხის ნაწილების და ნაკლები ხარისხის კომპონენტების შემცირებას ზუსტად დაგეგმილი კომპონენტების შექმნით, რაც შეიძლება შეუზოგოს ან მაქსიმალურად გაზარდოს მოგება. ჰიდრავლიკური პრესის მიერ უწყვეტი და მეთოდური მანიპულირება ან მოდელირება მასალებზე უზრუნველყოფს შეცდომებისა და ნაკლები ხარისხის პროდუქციის მინიმალურ დონემდე შემცირებას, რაც უზრუნველყოფს ხარისხის და მოგებიანობის გაუმჯობესებას წარმოების პროცესში. ჰიდრავლიკური პრესი აუცილებელია სამრეწველო პროცესში, რომელიც აკმაყოფილებს ბაზრის მოთხოვნებს, სადაც საჭიროა ზუსტი წნევის კონტროლი სისქის მისაღებად და უმცირესი ნაგავის გაჩენა მუდმივად წარმოებული ნაწილების შემთხვევაში.

Რატომ არის ჰიდრავლიკური პრესები მნიშვნელოვანი ზუსტი წარმოების პროცესებისთვის

Ეს ჰიდრავლიკური პრესები გამოიყენება მაღალი სიზუსტის წარმოებაში. ეს არის ჰიდრავლიკურად მართვადი პრესები, რომლებიც ახდენენ წნევის მოქმედებას მასალებზე და ამ წნევით ფორმავენ ნაწილებს. ასეთი ჰიდრავლიკური სისტემით აღჭურვილი პრესები შექმნილია იმისათვის, რომ უზრუნველყოთ წნევის აღდგენადობა და შედეგების გარანტირება. ეს ნიშნავს, რომ სიზუსტის ხარისხი საკმაოდ მნიშვნელოვანია და ასეთი ინდუსტრიები, როგორიცაა ავტომობილგამომწვევი, ავიაკოსმოსი და ელექტრონიკა, ვერ იძლევიან დაბალი დონის შეცდომებს გადამუშავების ხარჯების გარეშე ან პროდუქის უარყოფის გარეშე. ჰიდრავლიკური პრესების გამოყენებით წარმოების მწარმოებლებს შეუძლიათ მუშაობა საკმაოდ მცირე დაშვებებით და წარმოება ხარისხიანი კომპონენტები საკმაოდ დაბალი ნაგავის დონით.

Რატომ არის ჰიდრავლიკური პრეს-მანქანები გარდამყოლების ბიზნესის პირველი არჩევანი

Ჰიდრავლიკური პრესის გაყიდვა. მოხმარების გათვალისწინებით, საწარმოო ბაზარზე გამომუშავებული მაღალეფექტური და მდგრადი გებრების მიმღებები აფასებენ ჰიდრავლიკური მუშაობის მნიშვნელობას. ისინი მყარი, უნივერსალური და მარტივად ადაპტირებადია სხვადასხვა მასალებისა და პროცესებისთვის. ჰიდრავლიკური პრესი შესაძლებელია გამოყენებულ იქნას სხვადასხვა წარმოების მოთხოვნების შესაბამისად და წარმოადგენს იაფ ალტერნატივას დიდი მასშტაბის დისტრიბუტორებისთვის. ჰიდრავლიკური პრესები ფავორიტები არიან დიდი მასშტაბის წარმოების მომხმარებლების შორის მათი ცნობილი ინვესტიციის შესაბამისი შედეგით, რომელიც გამოხატულია ხარისხიანი შესრულებით და საიმედოობით.

Მაღალი სიზუსტის წარმოებისთვის ჰიდრავლიკური პრესის არჩევისას გასათვალისწინებელი მნიშვნელოვანი ასპექტები

Მნიშვნელოვანი ფაქტორები, რომლებიც განიხილება ჰიდრავლიკური პრესის არჩევისას ჰიდრაულიკური წნევის მაშინი ზუსტი ნაწილების წარმოებაში გამოყენებული. პირველ რიგში, შესყიდვის მხარემ უნდა დაინტერესდეს საშუალო ზომის, მაგრამ ძლიერი და საიმედო ჰიდრავლიკური სისტემით აღჭურვილი მანქანის შეძენით, რომელიც შესყიდვის მხარეს მისცემს სტაბილურ წნევას და კონტროლს. საჭიში უნდა ჰქონდეს ასევე მტკიცე ჩარჩო და საწოლი, რათა გაუმკლავდეს ზუსტი ფორმირებისა და ფორმის დანიშნულების საქმიანობებთან დაკავშირებულ ძალიან მკაცრ შეზღუდვებს. სხვა მნიშვნელოვანი თვისებები: პროგრამირებადი კონტროლის სისტემები. პროგრამირებადი კონტროლის სისტემები არის სხვა თვისებებიც, რომლებიც უნდა განიხილებოდეს ზუსტობის გასაუმჯობესებლად, ცვლადი სიჩქარისა და წნევის პარამეტრების მიზნით, რათა უზრუნველყოს მოქნილობა და უსაფრთხოების თვისებები, როგორიცაა ავარიული გაჩერების ღილაკები და მანქანის გადატვირთვისგან დაცვა. ასეთი ატრიბუტები არის ძირეული თვისებები, რომლებიც საშუალებას აძლევს მწარმოებლებს მიაღწიონ უმაღლეს შესრულების დონეს და მუდმივობას მაღალი სიზუსტის წარმოებაში.

Შინაარსის ცხრილი

- Ჰიდრავლიკური პრესების სარგებლობა მაღალი სიზუსტის მქონე წარმოებისთვის

- Როგორ ქმნიან ჰიდრავლიკური პრესები ერთგვაროვან ხარისხს მასობრივ წარმოებაში

- Რატომ არის ჰიდრავლიკური პრესები მნიშვნელოვანი ზუსტი წარმოების პროცესებისთვის

- Რატომ არის ჰიდრავლიკური პრეს-მანქანები გარდამყოლების ბიზნესის პირველი არჩევანი

- Მაღალი სიზუსტის წარმოებისთვის ჰიდრავლიკური პრესის არჩევისას გასათვალისწინებელი მნიშვნელოვანი ასპექტები

EN

EN AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI SQ

SQ TH

TH TR

TR MS

MS MK

MK HY

HY AZ

AZ KA

KA MN

MN KK

KK UZ

UZ KY

KY